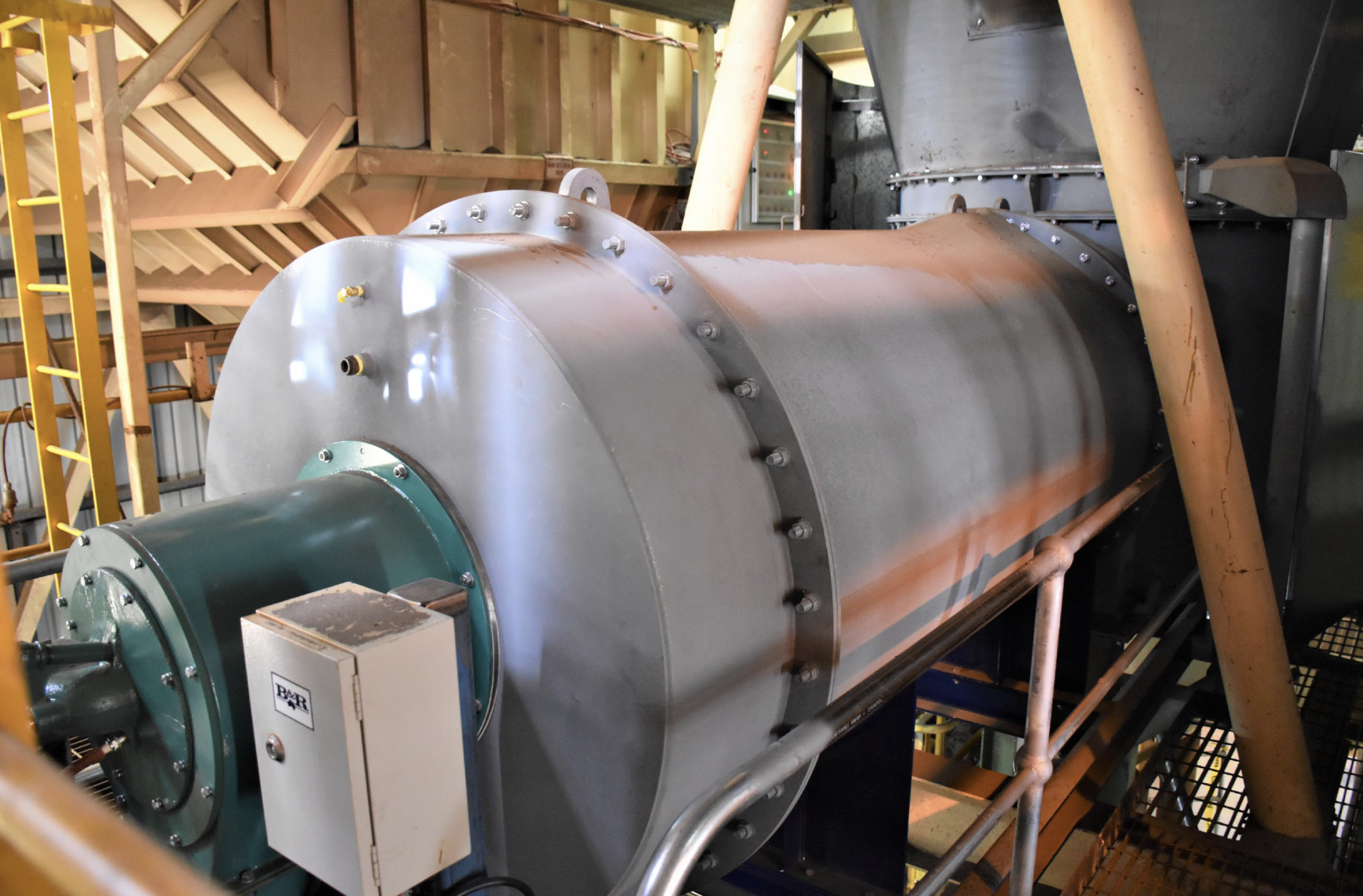

dvanced technology is now at the heart of mineral processing equipment design. The goal is clear: increase output, reduce downtime, and lower energy use. Modern equipment is no longer built just for function it is designed for smart performance. With every upgrade, machines become more efficient, safer to operate, and easier to maintain. Automation, digital monitoring, and precision engineering are transforming how materials are sorted, crushed, screened, and processed. These improvements are not just helpful they are now essential for keeping operations competitive and cost-effective.

Key Features of Cutting-Edge Mineral Processing Equipment

The latest equipment integrates powerful design elements that boost productivity while cutting waste. Whether handling coarse materials or fine particles, modern machines offer precise control and consistent performance. JXSC offers comprehensive mineral processing solutions, from crushers to separators, meet the industry’s highest standards for performance and longevity. Key technologies include:

- Automation and Control Systems

Machines now come with built-in automation. Sensors, real-time feedback, and programmable logic systems let operators manage processes with greater accuracy and minimal manual effort.

- Energy-Efficient Drives and Motors

Energy savings are built into every new design. Equipment runs with motors that consume less power while delivering maximum output, reducing long-term operating costs.

- Modular and Compact Structures

Many machines are now modular, meaning they can be quickly assembled, upgraded, or moved. Compact layouts save space without sacrificing performance, making them ideal for various site conditions.

- Wear-Resistant Materials

Equipment lasts longer thanks to improved construction materials. Tougher surfaces reduce wear and tear, keeping performance consistent while lowering replacement frequency.

- Advanced Screening and Sorting Tech

From vibrating screens to air separators, smarter systems now handle materials more accurately. This leads to less waste and better product recovery.

Benefits You Can Count On

Investing in cutting-edge mineral processing equipment delivers both immediate and long-term advantages:

- Faster Processing Time – High-speed systems cut cycle times and boost throughput.

- Higher Accuracy – Smart systems reduce errors and increase material recovery rates.

- Lower Maintenance Costs – Durable parts and self-monitoring systems mean fewer breakdowns.

- Increased Safety – Enclosed systems and automated features reduce the need for manual contact.

- Data-Driven Decisions – Real-time monitoring allows for quicker adjustments and better process control.

Technology That Adapts to Your Needs

Modern designs are flexible. Whether you are scaling up production or working in a confined space, equipment can be adapted to suit your exact requirements. Many machines now allow remote access, predictive maintenance, and system updates via digital platforms. This not only ensures smoother operation but also allows teams to plan ahead with real-time performance data.

Every element in mineral processing equipment is now driven by technology. From design to performance, today’s machines are built to meet rising demands in productivity, efficiency, and sustainability. Choosing equipment with cutting-edge technology is not just a smart move it is the standard for successful operations. Whether improving an existing setup or planning a new facility, embracing these advanced features ensures better outcomes and long-term results.